- NEWS CATEGORIES

- TONGDA NEWS

- INDUSTRY NEWS

- COMMON PROBLEM

How can China's sealing machine improve its international competitiveness

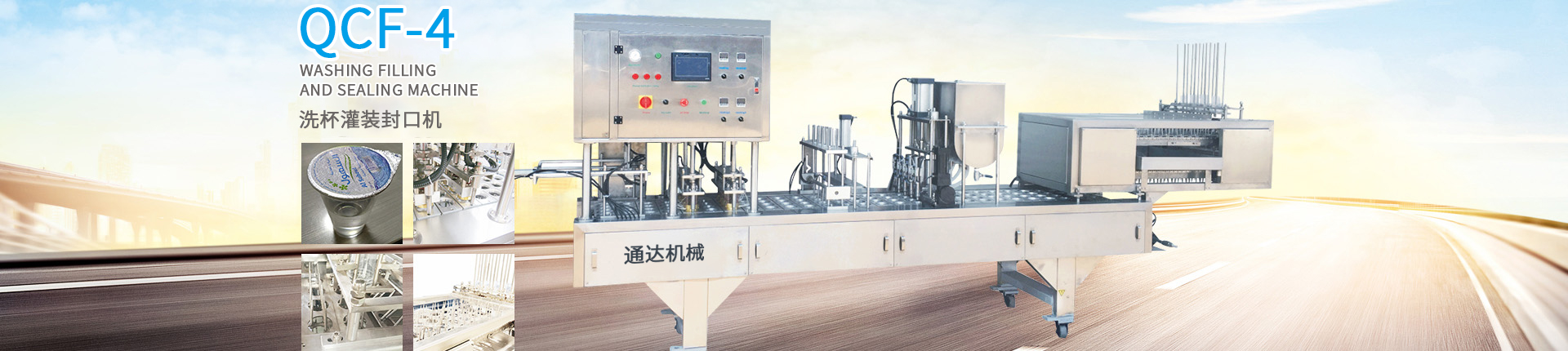

The rapid development of China's beverage and beer markets has also driven the development of the packaging machinery industry. Since the 1980s, China has imported a large number of beverage and beer packaging machinery every year. China's sealing machine has been developed for more than ten years now. Nowadays, it has a variety of equipments on the market. It is also widely used in food, beverage, pharmaceutical, chemical and other industries. It can be effectively used by sealing machine. The quality and safety of the products are guaranteed, and the appearance of the products is more beautiful, which helps to promote the sales of the products. It is an indispensable equipment in the beverage, food, pharmaceutical, chemical and other industries.

In recent years, China has introduced a series of policies to support the development of the machinery industry, including the sealing machine. China has formulated relevant preferential measures to promote the development of the sealing machine industry, continuously improve the technology blowing, and enhance innovation. Capacity, improve production efficiency, however, there is still a big gap between China's sealing machine technology and foreign countries. Many manufacturers have poor quality and low stability due to lack of technology in the production of equipment. The production efficiency is low, and the products produced can not meet the production needs of customers far, so long-term development will not adapt to the development of the market. Therefore, in order to break the status quo, China's sealing machine manufacturers must take active measures to further accelerate the development of the sealing machine industry.

According to the current status quo in China, the development trend of China's sealing machine in the recent three years of Zui should be: learning, innovation, technology combination, starting from the technology of production sealing machine, improving the efficiency of sealing machine and automating planning your loneliness In order to produce related supporting facilities and speed up the production efficiency of China's sealing machine; to produce some sealing equipment suitable for small and medium-sized enterprises, China's small and medium-sized enterprises account for a large proportion in the market; introduce some advanced technologies, such as: electromechanical Some advanced technologies, such as integrated technology, microelectronics technology and modular technology, have made China's sealing machines develop in the direction of automation, chemicalization and functionalization.

Through the support of the government and the promotion of various domestic industries, the development space of China's sealing machine industry is expanding. Therefore, domestic sealing machine manufacturers must seize the opportunity and continue to develop. Only in this way can they go out and move toward world.

In recent years, with the continuous improvement of domestically produced equipment, domestically produced equipment has basically replaced imported equipment. In 1986, China Light Industry Machinery Corporation of the former Ministry of Light Industry introduced a 20,000 bottles/h beer production line from Germany KHs through a combination of technology and trade. In 1993, it imported 36,000 bottles/h from the KHs company with a contemporary technology level. The beer bottling production line has made a leap-forward development of domestic processing technology and technology through the introduction of technology, digestion and absorption. China's beer beverage manufacturing technology and equipment manufacturing technology have also reached a new level, and some filling and sealing equipments have reached At a higher level, the level of packaging production lines has also been improved, and it can already meet the needs of medium-sized enterprises. Some of them can replace imported equipment, and the export volume has increased year by year. Most of these machines are high-speed automated production lines with high reliability and high output. Some of the equipments are advanced models in today's world. The packaging level of some beverage and beer companies in China has been synchronized with developed countries.

Glass bottle filling rotary (pressure) cover machinery, especially beverage, beer glass rotary (pressure) cover machinery and food packaging machinery, with high speed, complete set, high degree of automation and good reliability. The development trend of the glass bottle filling rotary (pressure) cover machine is multi-functional and high-yield.愁 浪 合 , _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ The filling speed of the high-speed, high-yield carbonated beverage filling machine is up to 800 cans/min. The filling valve of the non-carbonated beverage filling machine is 50-100 heads, and the filling speed is up to 500 cans/min.

High technical content, high reliability, full-line self-control level and full line rate; online detection device and metering device are complete, can automatically detect various parameters, measurement; 'set machine, electricity, 'gas, light, magnetic one High-tech products are the current development trend of the filling machinery industry.

The complete supply capacity is strong. Such as a beverage filling line, filling and capping combination, realistic productivity and theoretical technology. The supplier can provide engineering design, installation and commissioning for the user, and then submit the user acceptance. For example, the simulation design technology will be widely used to store various machine units in the form of a database, and the digital image will be input to the computer, and then the actual production indicators and data, possible failures, etc. will be input to the computer factory. The engineer operates according to the actual work situation, demonstrating the production capacity, the scrap rate, the production ring book matching, the production line bottleneck, etc., and the model can be modified according to the user's opinion until the user is satisfied.

Current filling machinery technology is commonly used in the development, design and manufacturing of food and beverage packaging. The development trend of filling machinery is to continuously improve the automation of the single machine to improve the automation control level and production capacity of the entire packaging production line, which can greatly improve the quality of food and beverage packaging production equipment products, and improve their domestic and international competitiveness.

High technical content, high reliability, full-line self-control level and full line rate; online detection device and metering device are complete, can automatically detect various parameters, measurement; 'set machine, electricity, 'gas, light, magnetic one High-tech products are the current development trend of the filling machinery industry.

Previous: Characteristics and trends of milk tea sealing machine